OPTICUT – Classification of pork primal cuts in quality groups

Sorting ham and loins in three quality groups: Good, Regular, and Poor.

Última modificación: 20 January 2022

The Spanish company Lenz Instruments S.L. in collaboration with the Irish firm GM Steel fabricators Ltd has developed a device (OPTICUT) to inspect pig carcasses for detecting WHC defects in the primal cuts (ham and loin) in a fast and non-destructive way. OPTICUT consists of a hand-held insertion probe (Ø 6mm) that integrates a miniaturized optical system coupled to a Near-Infrared Spectroscopic system to assess the quality of the primal cut in less than 1 second.

OPTICUT performs an optical analysis inside the meat using the technique of Fiber Optic Coupled Diffuse Reflectance NIR Spectroscopy (FO-NIRS). To perform this analysis, the system incorporates a probe with minimally invasive penetration (similar to a pH probe), with a unique and patented design. Based on the light spectrum obtained from inside the product, the system uses intelligent algorithms that provide the user with an index of product quality, and that is related to the water holding capacity and texture of the meat.

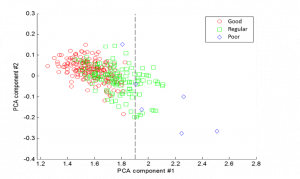

The analysis of the spectra obtained reveals statistically significant differences between the different groups of samples (good, regular, and poor). The first experimental results obtained show that the OPTICUT probe can effectively discriminate poor meat (PSE meat) from good meat (subsets 1 and 3). The data obtained determines that the proposed model provides good precision of classification, being able to detect more than 85% of the hams of the regular and poor category that have quality defects and 100% of the hams of the poor category. It should be noted that the percentage of success is determined by the uncertainty of the reference method and the measurement method itself which were limited to the inspection of one single spot of the meat.

Figure 2 Spectral analysis with two principal components PCA1 and PCA 2 (left)

OPTICUT is intended to be used in pork processing lines to classify and separate pork carcasses into different quality categories. The probe has been designed to fulfill the requirements of Industry 4.0, and can be easily interfaced with other smart sensors, machines, and RFID readers.